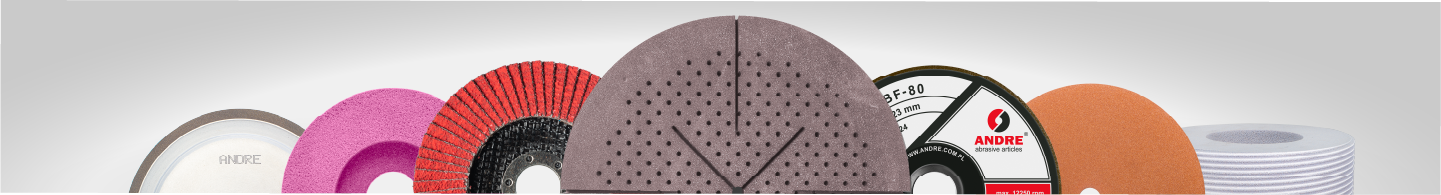

Superhard abrasive tools

Superhard abrasive tools by ANDRE ABRASIVE ARTICLES, feature disproportionately higher performance than conventional grinding wheels. SUPERHARD tools use diamond or cubic boron nitride (CBN) abrasive grains to achieve the highest performance in grinding. Thanks to the use of appropriately selected technical characteristics, it is possible to prepare products with the highest parameters, meeting the expectations of even the most demanding users. ANDRE superhard abrasive tools are made in accordance with safety standard EN 13236 - Safety requirements for superhard abrasive tools.

Bonds - resin, ceramic or electroplated

SUPERHARD abrasive tools with diamond and cubic boron nitride (CBN) grains find their special use in precision grinding of hard and hard-to-machine materials. The specificity of SUPERHARD results from both the high hardness of diamond and boron nitride and the bond used. The characteristics of the binder used determine the properties of the tools, including their performance, ability to hold shape or influence the quality of the machined surface. Resin bonds are characterized by efficient, cool and gentle grinding while removing as much material as possible. The ceramic bond increases the efficiency of grinding wheels - because, due to their structure, they better transfer coolant to the point of contact between the grinding wheel and the workpiece, and disperse the grinding residue. The electroplating bond allows for strong bonding while providing high exposure of abrasive grains. Grinding wheels with this bond are ideal for grinding with large allowances and where complex shapes are required (profile grinding wheels).

SUPERHARD tools from ANDRE, thanks to our many years of experience in the production of professional abrasive tools, are of high quality and safety in accordance with EN 13236. Our team of technology specialists responds to the individual needs of end users by manufacturing special application abrasive tools with strictly designed physical and mechanical parameters dedicated to specific grinding operations.

Example of a superhard abrasive tool design

Applications of superhard abrasive tools

Various operations

Sharpening of band and circular saws, cutting tools, e.g.: lathe tools, milling cutters, drills made of HSS and sintered carbide

Grinding of hard materials, dry and wet, on CNC and conventional grinders

Cutting-off various materials with very high efficiency

Various industries

Used in a wide diversity of industries such as automotive, tooling, as well as foundry and woodworking

Features of superhard abrasive tools

high productivity during operation, rapid material removal during grinding or cutting-off

long life of the grinding wheel

high shape durability

precise machining of hard and difficult-to-machine materials

uniform surface quality of machined materials

"cool" grinding

Top quality raw materials

At ANDRE ABRASIVE ARTICLES, modern hard abrasives are used in the production of SUPERHARD tools. Diamond and cubic boron nitride (CBN) grains are the hardest abrasives available and have a much higher hardness compared to traditional abrasives such as electro-corundum or silicon carbide. However due to their chemical properties diamond grains are used for machining different materials than CBN.

D - Diamant, (in der Regel synthetischer Diamant)

B - Borazon, in. CBN, cBN (kubisches Bornitrid)

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE is successively improving its technological process to offer abrasive tools that provide increasingly better utility values and a high safety factor, in accordance with current standards, for superhard tools, among others, EN 13236 - Safety requirements for superhard abrasive tools. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.

FEDERATION OF EUROPEAN PRODUCERS OF ABRASIVES