TYPE 42

REINFORCED DEPRESSED CENTRE CUTTING-OFF WHEELS

TYPE 42 reinforced wheels are a numerous and popular group of universal and special abrasive tools for cutting through various materials. They are widely used at construction sites, steel construction plants, shipyards, mechanical engineering plants, steel mills, foundry and other industries, as well as in smaller workshops and tool shops. Depending on the size and requirements, they work with a variety of grinders - cutters: manual, stationary electric, pneumatic or petrol. These grinding wheels are mechanically reinforced, designed for operation at a speed of 80 [m/s]. For these grinding wheels, face grinding is not a permitted operation.

ANDRE TYPE 42 reinforced resin bonded wheels are produced on the basis of a specially developed composition of abrasive grains in combination with a refined system of active fillers.

42 - D x U x H

Examples of labeling:

42 - 125x2,5x22,23-95A30RBF-80 INOX

Download

A line of professional solutions that meets the condition of a good efficient product at a good price. Dedicated definitely for professional applications.

VERSION STANDARD

For cutting-off steel, cast iron and cast steel materials; especially objects with larger solid cross-sectional areas: round, rectangular types of rods, flat bars, as well as sheet metal, casting overmolds.

|

STANDARD |

||||||

|

Dimensions [mm] |

Charakteristics |

RPM |

||||

|

115 × 2,5 × 22,23 |

95A30RBF |

13300 |

||||

|

115 × 3,0 × 22,23 |

95A30RBF |

13300 |

||||

|

125 × 2,5 × 22,23 |

95A30RBF |

12250 |

||||

|

125 × 3,0 × 22,23 |

95A30RBF |

12250 |

||||

|

150 × 3,0 × 22,23 |

95A24RBF |

10200 |

||||

|

180 × 3,0 × 22,23 |

95A24RBF |

8500 |

||||

|

230 × 2,5 × 22,23 |

95A24RBF |

6650 |

||||

|

230 × 3,0 × 22,23 |

95A24RBF |

6650 |

||||

*) Other parameters available according to individual arrangements.

VERSION EXTRA

Enhanced hardness. For cutting-off steel, cast iron and cast steel materials.

|

EXTRA |

||||||

|

Dimensions [mm] |

Charakteristics |

RPM |

||||

|

125 × 2,5 × 22,23 |

95A30TBF |

12250 |

||||

|

125 × 3,0 × 22,23 |

95A30TBF |

12250 |

||||

|

150 × 3,0 × 22,23 |

95A24TBF |

10200 |

||||

|

180 × 3,0 × 22,23 |

95A24TBF |

8500 |

||||

|

230 × 2,0 × 22,23 |

95A36TBF |

6650 |

||||

|

230 × 3,0 × 22,23 |

95A24TBF |

6650 |

||||

*) Other parameters available according to individual arrangements.

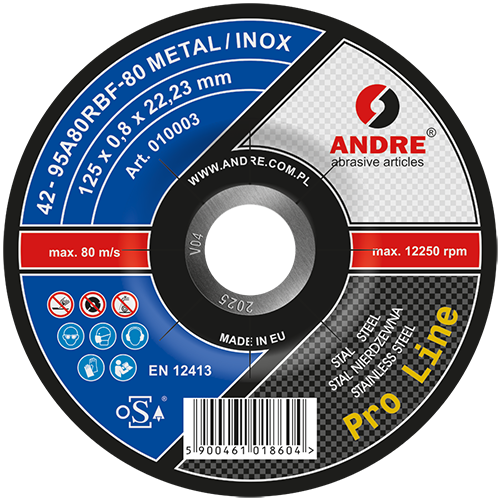

VERSION METAL/INOX

Thin grinding wheels for efficient, precision cutting of universal, structural, tool, stainless and acid-resistant steels. They are free of iron, sulfur and chlorine.

|

METAL/INOX |

||||||

|

Dimensions [mm] |

Charakteristics |

RPM |

||||

|

125 × 0,8 × 22,23 |

95A80RBF |

12250 |

||||

|

230 × 2,0 × 22,23 |

95A36RBF |

6650 |

||||

*) Other parameters available according to individual arrangements.

VERSION INOX

For cutting stainless and acid-resistant steels. In a thin version for efficient precision cutting and in a typical version for general use. They are free of iron, sulfur and chlorine.

|

INOX |

||||||

|

Dimensions [mm] |

Charakteristics |

RPM |

||||

|

125 × 0,8 × 22,23 |

95A80RBF |

8500 |

||||

|

125 × 3,0 × 22,23 |

95A30RBF |

6650 |

||||

*) Other parameters available according to individual arrangements.

VERSION SERIA 500

Special grinding wheels for cutting steel objects, and especially for efficient cutting of rubber conveyor belts with steel cables or steel cables themselves.

|

SERIA 500 |

||||||

|

Dimensions [mm] |

Charakteristics |

RPM |

||||

|

180 × 3,0 × 22,23 |

95A24U9BF |

12250 |

||||

|

230 × 3,0 × 22,23 |

95A24U9BF |

12250 |

||||

*) Other parameters available according to individual arrangements.

VERSION STONE

For cutting through concrete, reinforced concrete, terrazzo, natural and artificial stones, ceramic materials, as well as hard, brittle cast iron.

|

STONE |

||||||

|

Dimensions [mm] |

Charakteristics |

RPM |

||||

|

115 × 3,0 × 22,23 |

98C30RBF |

13300 |

||||

|

125 × 3,0 × 22,23 |

98C30RBF |

12250 |

||||

|

230 × 3,0 × 22,23 |

98C24RBF |

6650 |

||||

*) Other parameters available according to individual arrangements.

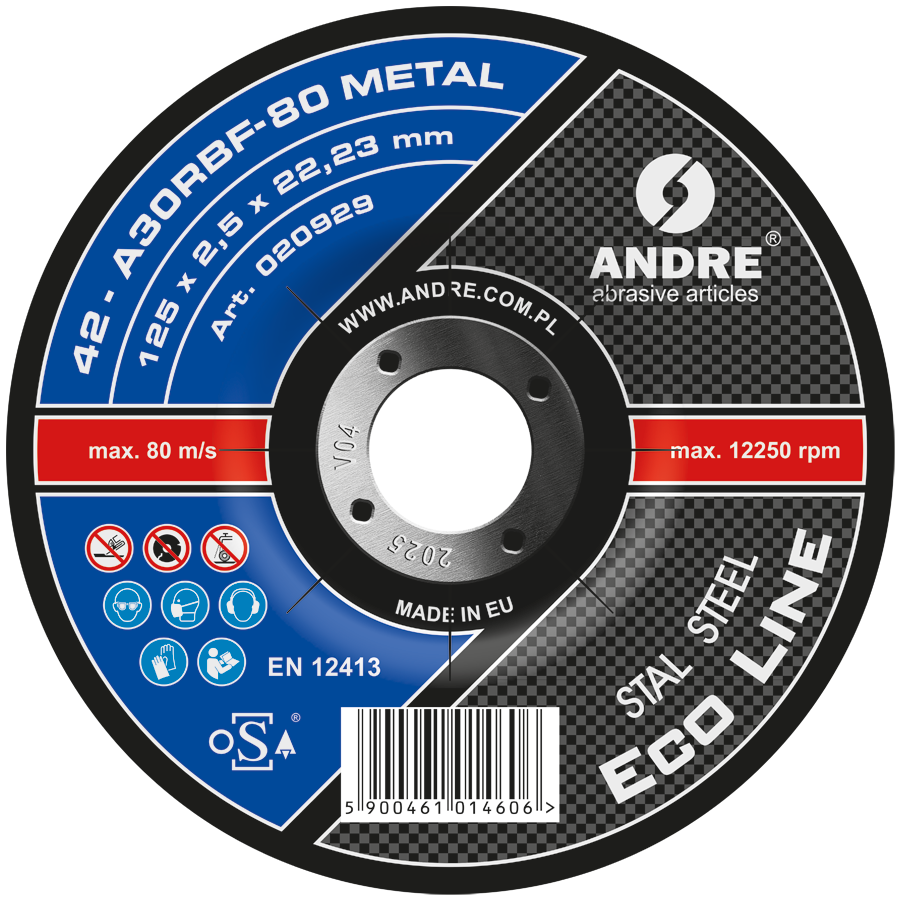

A line of economic solutions that meets the condition of a good price for the customer, while providing good performance and a high safety factor.

VERSION METAL

Grinding wheels intended for cutting-off operations that do not require high utility values. Application - similar to the Pro Line product line Standard version.

|

METAL |

||||||

|

Dimensions [mm] |

Charakteristics |

RPM |

||||

|

115 × 3,0 × 22,23 |

A30RBF |

13300 |

||||

|

125 × 2,5 × 22,23 |

A30RBF |

12250 |

||||

|

125 × 3,0 × 22,23 |

A30RBF |

12250 |

||||

|

180 × 3,0 × 22,23 |

A24RBF |

8500 |

||||

|

230 × 2,0 × 22,23 |

A36RBF |

6650 |

||||

|

230 × 3,0 × 22,23 |

A24RBF |

6650 |

||||

*) Other parameters available according to individual arrangements.

Application table - TYPE 41 and TYPE 42

|

Application |

TYPE 41 / TYPE 42 |

||||||||||||

|

ECO LINE |

PRO LINE |

MASTER LINE |

|||||||||||

|

METAL |

METAL/INOX |

STANDARD |

EXTRA |

METAL/INOX |

INOX |

ALUMINIUM |

SERIA 500 |

RAIL |

STONE |

METAL |

METAL/INOX |

||

|

Steel - general purpose |

x |

x |

x |

x |

x |

x |

|||||||

|

Constructional steel |

- large cross-sectional areas |

x |

x |

x |

x |

x |

|||||||

|

- small cross-sectional areas |

x |

x |

x |

x |

x |

x |

x |

||||||

|

- thin sheets, pipes, thinwalled profiles |

x |

x |

x |

x |

x |

x |

x |

x |

|||||

|

- operating platform grids |

x |

||||||||||||

|

Tool steel |

x |

x |

x |

x |

x |

x |

|||||||

|

Stainless and acid resistant steel |

- general applications |

x |

x |

x |

x |

||||||||

|

- thin sheets, pipes, thinwalled profiles |

x |

x |

x |

x |

|||||||||

|

Railway rails |

x |

||||||||||||

|

Steel wire ropes |

x |

||||||||||||

|

Chilled cast iron |

x |

||||||||||||

|

Ductile cast iron |

x |

x |

x |

x |

|||||||||

|

Cast steel |

x |

x |

x |

x |

|||||||||

|

Aluminium and its alloys |

x |

||||||||||||

|

Non-ferrous metals |

x |

||||||||||||

|

Concrete, terrazzo |

x |

||||||||||||

|

Stone, ceramics |

x |

||||||||||||

The presented abrasive tools ANDRE ABRASIVE ARTICLES have been manufactured based on knowledge and long-term experience of cooperation with customers.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.