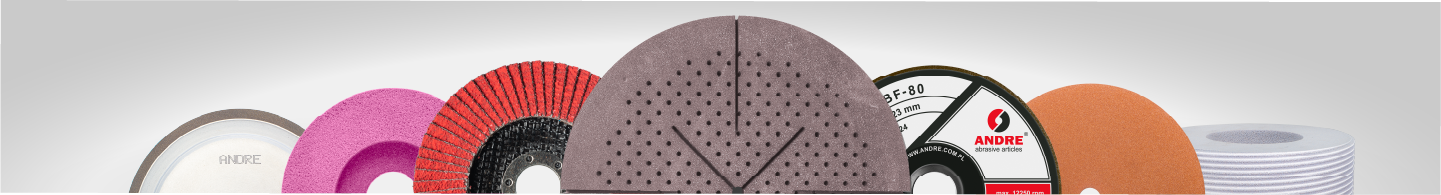

TYPE 1

FLAT GRINDING WHEELS

TYPE 1 flat wheels constitute the most numerous group of general and special-purpose abrasive tools. Depending on your needs, these wheels can be reinforced with steel rings and/or fiberglass discs and a fine center zone where necessary. They are used for precision and rough grinding of various materials, e.g. hard and soft steels, stainless steels, cast iron, aluminum, bronze, brass, concrete, stone, terrazzo, ceramics, sharpening of cutting tools. They are used on stationary grinders, swing frame grinding machines, electric and pneumatic hand-held grinders, sharpening machines and grinding units.

ANDRE TYPE 1 grinding wheels with resin bond are manufactured on the basis of brown aluminium oxide (95A), white aluminium oxide (99A), pink aluminium oxide (CRA), black silicon carbide (98C) and green silicon carbide (99C), among others. For special applications, ANDRE also offers other combinations of abrasive grains with excellent performance characteristics.

1 - D x T x H

Example of labeling:

1 - 200x25x32-95A24P6B51-50

1 - 200x25x32-95A24P6B51-50

Download

Parameters of the offered grinding wheels of the presented type

| TYPE 1 | ||

| Dimensions [mm] | ||

| D | T | H |

| 20 | 2 - 25 | 6 |

| 25 | 2 - 20 | 12 |

| 30 | 2 - 25 | 8; 10 |

| 35 | 2 - 25 | 10 |

| 40 | 2 - 30 | 10; 13; 16 |

| 45 | 2 - 30 | 10 |

| 50 | 2 - 25 | 8 |

| 2 - 35 | 7; 13; 16 | |

| 2 - 40 | 20 | |

| 60 | 2 - 35 | 13; 16; 20 |

| 65 | 2 - 45 | 16; 20; 32 |

| 75 | 2 - 35 | 10; 13 |

| 2 - 50 | 20 | |

| 80 | 4 - 25 | 10 |

| 4 - 40 | 8; 12,7; 32 | |

| 4 - 35 | 16; 22,2 | |

| 4 - 50 | 20 | |

| 90 | 4 - 60 | 20 |

| 4 - 35 | 30; 32 | |

| 100 | 4 - 50 | 20 |

| 4 - 35 | 22,2 | |

| 4 - 40 | 32 | |

| 112 | 4 - 25 | 22,2; 32 |

| 115 | 4 - 35 | 20; 32 |

| 125 | 4 - 15 | 12,7 |

| 4 - 50 | 20 | |

| 4 - 60 | 32 | |

| 127 | 4 - 25 | 12,7 |

| 150 | 4 - 35 | 10; 16 |

| 4 - 25 | 12,7 | |

| 4 - 50 | 20 | |

| 4 - 30 | 25,4 | |

| 4 - 50 | 32; 51 | |

| 160 | 4 - 40 | 12,7; 32 |

| 175 | 4 - 40 | 20; 32 |

| 4 - 25 | 76 | |

| 180 | 4 - 40 | 20; 32; 51 |

| 200 | 4 - 40 | 12,7; 20; 25,4; 51 |

| 4 - 60 | 32 | |

| 4 - 35 | 76 | |

| 3 - 20* | 32; 51 | |

| 205 | 2 - 20* | 76,2 |

| 225 | 2 - 20* | 76,2 |

| 230 | 5 - 35 | 22,2; 25,4; 32; 50; 60; 100 |

| 250 | 5 - 30 | 22,2 |

| 5 - 40 | 25,4; 32; 51; 60; 76; 120;127 | |

| 255 | 2 - 25* | 76,2; 127 |

| 285 | 1,5 - 3,5* | 203,2 |

| 295 | ||

| 300 | 5 - 40 | 25,4 |

| 5 - 30 | 40 | |

| 5 - 50 | 32; 50; 51; 60; 76 | |

| 5 - 80 | 127 | |

| 305 | 2,5 - 25* | 127 |

| 1,5 - 25* | 203,2 | |

| 320 | 2 - 25* | 203,2 |

| 350 | 2,5 - 25* | 127 |

| 5 - 65 | 32; 51; 127 | |

| 5 - 100 | 203; 203,2 | |

| 400 | 5 - 80 | 40; 51; 80; 127; 150; 203; 203,2 |

| 406 | 2,5 - 25* | 203,2; 304,8 |

| 450 | 8 - 80 | 51; 127; 150; 203; 203,2 |

| 500 | 8 - 100 | 40; 51; 127; 150; 152; 152,4 |

| 8 - 35 | 76 | |

| 8 - 140 | 203; 203,2 | |

| 8 - 200 | 304,8; 305 | |

| 6 - 25* | 304,8; 305 | |

| 508 | 6 - 25* | |

| 600 | 12 - 120 | 76;127; 203; 203,2; 304,8; 305 |

| 610 | 12 - 200 | 203; 203,2; 304,8; 305 |

| 750 | 20 - 100 | 304,8; 305 |

| 762 | 20 - 100 | 304,8; 305 |

*) Grinding wheels for processing drills and cutters

**) Other parameters (dimensions, profiles) available according to individual arrangements.

Examples of manufactured grinding wheels of the presented type

For rough grinding of workpieces, e.g. cleaning of castings, machining of forgings and steel construction components, reconditioning

|

95A |

||||

|

Code |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

In a box |

|

110217 |

200 × 25 × 32 |

95A24P6B51 |

50 |

5 |

For sharpening band saws.

|

99A |

||||

|

Code |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

In a box |

|

120130 |

150 × 8 × 32 |

99A60S6B88 FORMULA "3" |

50 |

100 |

For rough and fine grinding of concrete, reinforced concrete, terrazzo, natural and artificial stone, ceramic materials, and for grinding hard, brittle cast iron.

|

98C |

||||

|

Code |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

In a box |

|

215914 |

400 × 50 × 127 |

98C24R5B374F1 |

50 |

15 - paleta |

The presented abrasive tools ANDRE ABRASIVE ARTICLES have been manufactured based on knowledge and long-term experience of cooperation with customers.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.