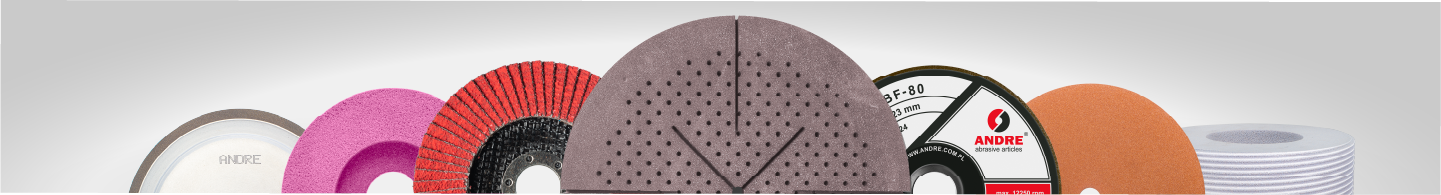

Grinding wheels with CRYSTALBOND

The innovative grinding wheels manufactured by ANDRE ABRASIVE ARTICLES bonded with CRYSTALBOND are a group of products that are dedicated to demanding grinding operations.

Processing of hard-to-machine materials

The use of glass crystalline bond makes it possible to produce grinding wheels with unique technical features. Tools bonded with the innovative CRYSTALBOND can be used in operations requiring efficient grinding of hard-to-machine materials or components with very high hardness.

Used in various stationary machines.

Thanks to our experience, ANDRE's new glass-bonded tools are of high quality.

Applications of glass-crystal bonded grinding wheels

Various operations

Grinding of hard-to-machine materials, stainless and acid-resistant inox steel, alloy steel, high-alloy steel and hardened steel, grinding of components with high hardness

Various industries

Used in many different industries such as automotive, machine building and aviation

Features of CRYSTALBOND grinding wheels

high performance grinding process

high quality of the ground surface

high resistance to brittle fracture

high self-sharpening ability

Innovative formulation and modern technology

During comprehensive research work aimed at composing the physico-chemical formulation of an innovative bond, ANDRE ABRASIVE ARTICLES, with the participation of specialists from scientific centers, developed and then implemented the technology of a completely new generation of glass-crystalline binding agents. This bond has specific properties, including, of particular importance, higher mechanical strength compared to conventional ceramic bonds.

Comparative tests of CRYSTALBOND and conventional grinding wheels

Machining process: circumferential axial grinding of cylindrical internal surfaces.

Workpiece: inner surfaces of bearing rings made of 100Cr6 steel (63±2 HRC), inner diameter: dw = 40 mm, width: bw = 18 mm.

Grinder: RUP 28P.

Abrasive tool: type 1 flat grinding wheels of 35×10×10 mm.

Grinding parameters:

- wheel peripheral speed ns = 27300 rpm,

- workpiece peripheral speed nw =400 rpm,

- grinding depth ae total = 0.20 mm,

- table axial feed rate: vfa=20mm/s.

- PCS: cooling lubricant - 5% aqueous solution of Castrol Syntilo RHS oil injected into the grinding zone by means of a flooding method.

Roughness Ra of the machined surface

Efficiency of the grinding process

The innovative CRYSTALBOND GRINDING WHEELS

...to meet your needs.

TYPE 1

FLAT GRINDING WHEELS

For efficient grinding of hard and difficult-to-grind materials

Get to know the products

High-quality, proven raw materials

At ANDRE ABRASIVE ARTICLES, the production of abrasive tools with an innovative glass-crystal bond uses modern, hard abrasives. At present, the most commonly used abrasive is white fused alumina.

99A - White fused aluminia

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.

FEDERATION OF EUROPEAN PRODUCERS OF ABRASIVES