GENERAL RULES FOR MARKING ABRASIVE TOOLS

Principles, elements, symbols in the marking of ANDRE abrasive tools

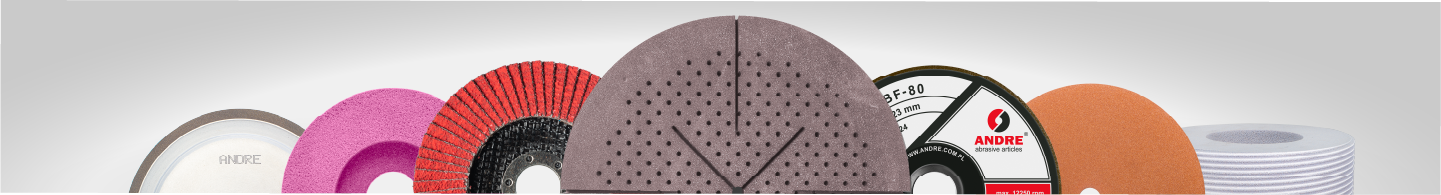

Proper labeling of abrasive tools by the manufacturer involves the application of the recommendations of the relevant standards, including graphic elements and adequate symbols. Sometimes manufacturers also use additional elements to improve the safety of using abrasive tools.

At ANDRE, abrasive tools are marked according to ISO 525 standard. The marking consists of groups of digit and letter symbols separated by "-". These are:

- shape markings - type + profile

- dimensions

- technical characteristics

- permissible operating speed (for grinding wheels)

- the name of manufacturer or logo

In ANDRE, various additional information in the form of either inscriptions or graphic signs is used as part of the labeling. Grinding wheels, segments and abrasive sharpening stones can be additionally marked with:

- colorful stripes according to the speed color code

- safety marks and/or certificates

- safety pictograms, symbols, restriction on use

- inscriptions specifying the application, e.g. "steel", "stone", "inox", "aluminum", etc.

- the symbol of the static imbalance of the grinding wheel, or the direction of mounting on the spindle.

It is worth noting that for different assortment groups (vitrified bonded abrasive tools, resin bonded abrasive tools, semi-flexible (coated) abrasive tools, super-hard abrasive tools, different marking forms are used, which meet the requirements of the relevant standards.

In addition, further in the section "technical information" you will find marking schemes for each group, as well as graphical examples of their characteristics.

Symbols and other elements of the ANDRE abrasive tool marking system

Shape markings (type + profile)

Shapes and the dimensions order are presented on separate subpages of the "Technical Information" section.

Dimensions

The data sheets provide information on the dimensions of abrasive tools supplied to ANDRE ABRASIVE ARTICLES customers. In addition, some of the datasheets contain examples of specific products.

Technical characteristics

Technical characteristics describe the features of an abrasive tool that have a direct impact on grinding results and work safety. The principles of selecting individual characteristic elements for the conditions and requirements of grinding operations are described on a separate subpage, and examples of typical applications will also be given.

Permissible operating speed for grinding wheels

Each grinding wheel has a specific permissible operating speed (rotational and peripheral). The working speed of the grinding wheel is expressed as follows:

Rotational speed n [min-1] = revolutions per minute or notation [1/min], [rpm].

Peripheral speed v [m/s-1] = meters per second or notation [m/s].

The formulas by which "n" can be expressed as a function of "v" and vice versa are as follows:

In the figure above, the relationship between the peripheral speed "v" and the number of revolutions "n" is graphically depicted.

The user must check that the highest permissible speed specified on the grinding wheel matches the speed specified on the machine.

In any case, the highest permissible peripheral speed of the grinding wheel must not be exceeded on the machine.

In machines with adjustable spindle speed or several operating speeds, the speed of the grinding wheel can be increased as the wheel wears, but without exceeding the maximum permissible peripheral speed of the wheel.

The maximum permissible rotational speed for mounted points also depends on the overhang length of the pin clamped. This relationship is given in the conversion table - Dependence of the maximum permissible rotational speed for mounted points on the overhang length of the pin L0=5 mm.

See the Conversion tables section for speed statements for common abrasive tool dimensions.

Additional elements of ANDRE abrasive tool markings (certificates, safety marks, pictograms, application)

In addition to the aforementioned markings, abrasive tools usually have a range of additional information in the form of various elements.

Pictograms and safety signs

The proper use of a particular tool is illustrated by safety pictograms.

Protect your hearing

Use eye protection

Use protection of respiratory system

Wear protective gloves

Read user manual / brochure

Wear protective footwear

Do not use a damaged grinding wheel

Wet grinding not permitted

Do not use on angle grinders

Face (side) grinding not permitted

Grinding allowed only at an angle greater than 10˚

Product lines of selected ANDRE abrasive tool groups

Some of ANDRE abrasive tools have graphics indicating the product line.

Product line for professional use

Economy product line

Product line for professional and specialized applications

Purpose/use of ANDRE grinding tools

ANDRE abrasive tools in the case of individual versions are marked with inscriptions that declare their proper purpose / application.

|

PURPOSE AND COLOR OF ABRASIVE TOOLS |

||||||

|

Version |

Color |

Purpose |

||||

|

METAL |

Tools for steel, cast iron |

|||||

|

STANDARD |

Tools for steel, cast iron |

|||||

|

EXTRA |

Tools with increased service life for steel, cast iron, etc. |

|||||

|

RAIL |

Tools for cutting railway and tram rails |

|||||

|

PROFIL |

Tools for cutting profile materials, e.g. platform grid |

|||||

|

SERIA 500 |

Tools for cutting steel objects, especially rubber conveyor belts with steel cables |

|||||

|

METAL/INOX |

Tools for structural steel, tool steel, acid-resistant steel, etc. |

|||||

|

INOX |

Tools for cutting stainless and acid-resistant steel |

|||||

|

ALUMINIUM |

Tools for non-ferrous metals and their alloys |

|||||

|

STONE |

Tools for concrete, reinforced concrete, stone, ceramics, etc. |

|||||

|

FOUNDRY |

Tools for cast iron |

|||||

Colorful stripes

Additional visual information about the maximum permissible operating speed of the grinding wheel is provided by colored stripes placed on the wheel according to the color code (extract from EN 12413).

|

COLORORFUL STRIPED [EN 12413] |

||||||

|

Peripheral speed [ms-1] |

Color |

Number of striped |

||||

|

50 |

1 x blue |

|||||

|

63 |

1 x yellow |

|||||

|

80 |

1 x red |

|||||

|

100 |

1 x green |

|||||

Non-standardized ANDRE products (non-standard dimensions, etc.)

Zusätzlich zu den oben genannten Kennzeichnungen sind Schleifwerkzeuge in der Regel mit einer Reihe von Zusatzinformationen in Form verschiedener Elemente gekennzeichnet.

When customers require tools with other than standard dimensions, shapes, profiles or characteristics, these can be subject to analysis. For more information, see the section on customized products.

It is worth noting that for individual assortment groups (vitrified bonded abrasive tools, resin bonded abrasive tools, semi-flexible (coated) abrasive tools, super-hard abrasive tools, different marking forms are used, which meet the requirements of the relevant standards. In addition, further in the section "Technical information" you will find marking schemes for each group, as well as graphical examples of their characteristics.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.