USE OF PROTECTIVE GUARDS

Examples of protective guard solutions used in grinding operations

Grinder designs provide various forms of protection for operators and the surrounding area during grinding operations, including appropriate protective guards. Due to safety reasons, protective guards are subject to standardized requirements.

Protective guards

In most cases, abrasive tools must be isolated by a suitable protective cover on the grinder.

These guards must be capable of catching broken wheel fragment effectively. Only that part of the grinding wheel that is involved exactly in grinding can be left unprotected. Certain operations may require even the entire working area to be guarded.The following wheel types may be operated without guards:

• mounted wheels and points Type 52

• cones and plugs with central threaded inserts Types 16 to 19

• resinoid wheels Type 4 of diameter ≤ 200 mm

GUARDS FOR BENCH AND PEDESTAL GRINDERS

Guards for bench and pedestal grinders

The maximum opening angle of the protective cover is 90°. The angle above the horizontal axis of the spindle must not exceed 50° and 65°.

Clearance between the periphery of the grinding wheel and the protective guard

When using grinding wheels with diameters D > 150 mm, the guard should be of such a design that permits its adjustment so that the clearance between the periphery of the wheel and the end of the guard does not exceed 5 mm. The position of the support must also be adjustable.

Rotating or pivoting inner guard

Fixed bench and pedestal grinders that run at the speed 63 m/s or more may be equipped with additional internal guards. These internal guards are designed to close the aperture in the main guard immediately in case of wheel breakage.

PROTECTIVE GUARDS FOR SWING FRAME GRINDERS

The opening angle of the swing frame grinder guard should not exceed 180°. The guard must cover at least half of the grinding wheel on each side.

GUARDS FOR STATIONARY CUTTING-OFF MACHINES

The maximum opening angle is 150°. The guard must cover the wheel on all sides except the cutting zone.

GUARDS FOR HAND-HELD GRINDERS

Guards for straight hand-held grinders

The maximum opening angle of the cover should not exceed 185°. The guard must be designed so that it can be opened (removed) from one side.

Guards for hand-held angle and face grinders

Guards for grinding wheels type 27 should have a maximum opening angle of 185°. They must be designed to be between the operator and the grinding wheel. In the case of straight or taper cup wheels, the guard must be adjustable and set so that only a specific part of the wheel remains exposed. In the case of adjustable guards, the uncovered part of the grinding wheel T0 (depending on the wheel thickness T) should not exceed the specified value.

The clearance between the periphery of the new grinding wheel and the cover must not exceed 6 mm.

GUARDS FOR INDUSTRIAL GRINDERS

Adjustable guards for grinding wheel with threaded inserts

For large grinding wheels used on industrial grinders, the cover must be adjusted and set so that only a specific part of the wheel remains exposed. The uncovered part of the grinding wheel T0, which depends on the thickness T of the wheel, must not exceed the specified value.

To=< 0.3T for T=<50 mm

To=< 0.2T for T>50 mm

The clearance between the periphery of the new grinding wheel and the guard must not exceed 12.5 mm.

Adjustable guards for grinding head with abrasive segments

For industrial grinders using segments, the adjustable guard must be set so that the uncovered portion of the segment L0 does not exceed 0.5 Lf. The clearance between the rim of the segment and the guard must not exceed 12.5 mm.

Totally enclosed working area

In case of precision grinding performed at speed over 63 m/s the grinding wheel must be totally enclosed. When a totally enclosed guard is used, the workpiece is fed in mechanical way with complete safety. In addition, in case of wheel breakage, the fragments of the wheel cannot be thrown out.

Example of a fully sealed work zone

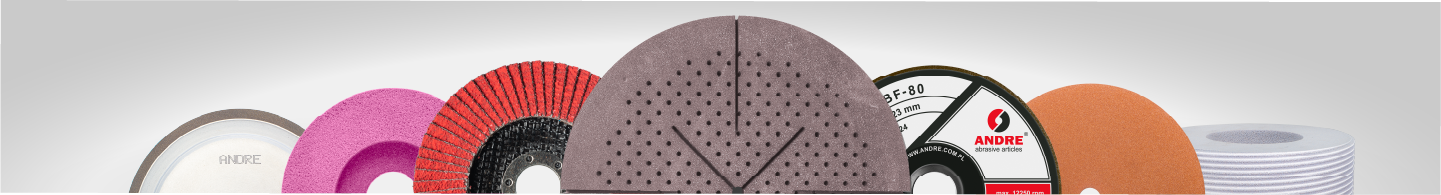

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.