Grinding of gearbox components

Transmissions must meet certain requirements, mainly in terms of reliability and service life. In order to achieve this, precise grinding process of all key components is necessary. Exceeding the permissible circularity tolerance of the shaft causes vibration and oscillation of the gearbox, and thus shortens its service life.

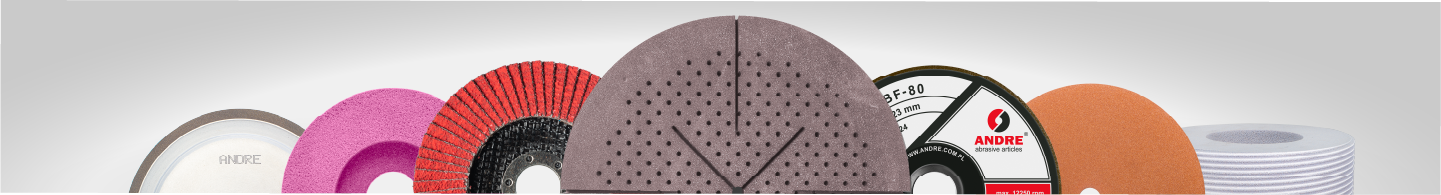

Many years of experience in this industry allows ANDRE to offer competitive, proven solutions.

SHAFT GRINDING

| TYPE 1M | TYPE 1X

1M - D x T x H

1X - D x T x H - no. pic.

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

1M |

740x85x304,8 |

99A90K7VE01NF7 |

63 |

|

1X |

600x85x203,2 |

99A90K7VE01NF7 |

63 |

[*] Ask the Sales Department about the full offer and available characteristics.

SYNCHRONIZER SLIDING SLEEVE GRINDING

| TYPE 1

1 - D x T x H

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

1 |

610x20x203,2 |

9A3X80L7VE01NF2 |

63 |

[*] Ask the Sales Department about the full offer and available characteristics.

SYNCHRONIZER RING GRINDING

| TYPE 1X

1 - D x T x H

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

1X |

400x25x203,2 |

9A3X1202K7VE04 |

63 |

[*] Ask the Sales Department about the full offer and available characteristics.

GEAR GRINDING WITH SINGLE RIB WHEEL

| TYPE 1P | TYPE 1X

1P - D x T x H

1X - D x T x H - no. pic.

|

Examples of implemented abrasive tools in industry [*] |

|||

|

Type |

Dimensions [mm] |

Characteristics |

Speed [m/s] |

|

1P |

200x25x80 |

9A5X80J12VE01NPP |

50 |

|

1P |

250x20x76,2 |

9A5X100I7VE01N |

50 |

|

1X |

100x20x36 |

9A5X80J8VE01 |

35 |

[*] Ask the Sales Department about the full offer and available characteristics.

GEAR GRINDING WITH WORMS

| TYPE 1X

1X - D x T x H - no. pic.

|

Examples of implemented abrasive tools in industry [*] |

||||

|

Type |

Dimensions [mm] |

Characteristics |

Module |

Speed [m/s] |

|

1X |

280x160x115 |

9A3X120H12VE01PP |

MOD2;a20;3Z;Rh |

63 |

[*] Ask the Sales Department about the full offer and available characteristics.

Since the beginning of its activity, ANDRE company has been focusing on high quality of its products. At ANDRE, every effort is made to ensure that products meet customers' individual needs and satisfy their highest expectations even in the most difficult grinding operations.

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.