Vitrified (ceramic) bonded abrasive tools

Vitrified (ceramic) bonded abrasive tools are one of the most popular solutions for precision grinding operations. ANDRE ABRASIVE ARTICLES offers a wide range of ceramic grinding wheels dedicated to many applications in different industries. By using appropriately selected technical characteristics of tools, including abrasives with different properties, it is possible to optimally adapt our tools to the requirements of users.

Vitrified bond

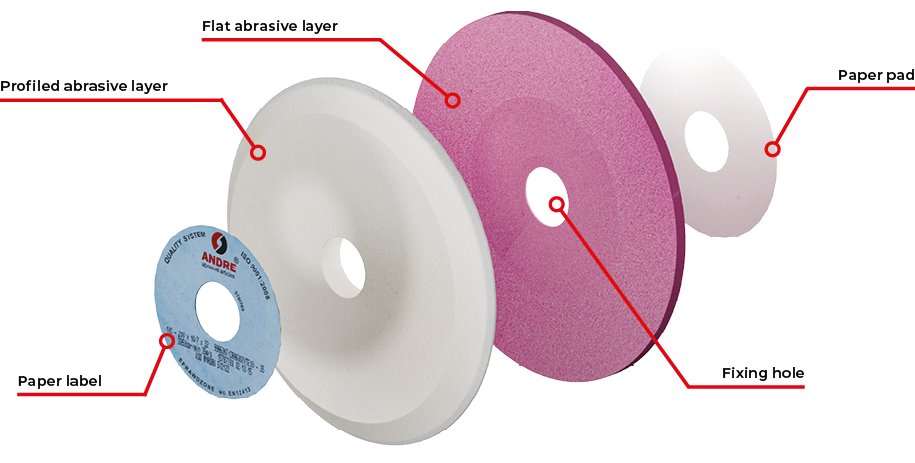

The bond acts as a link between the individual abrasive grains. The durability of this connection translates directly into tool properties, including productivity, workpiece surface quality and safety.

An important element of vitrified bonds is the pores formed in the space between the abrasive grain and the bond. They allow the coolant to penetrate the contact zone between the tool and the workpiece surface, providing better cooling of the workpiece and easier chip evacuation, which has a significant impact on the life of the abrasive tool. Prevents sealing up of the active surface, resulting in increased tool life.

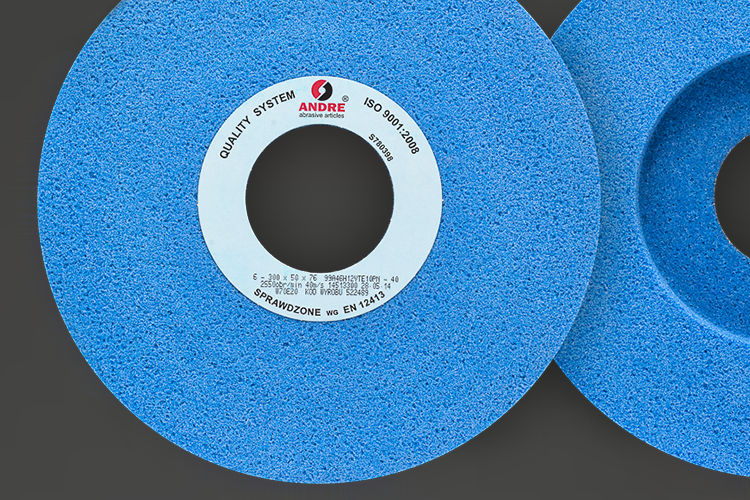

ANDRE tools with ceramic binder are characterized by high quality due to our many years of experience. Our team of technology specialists responds to the individual needs of end users by manufacturing abrasive tools with strictly designed physical and mechanical parameters dedicated to specific grinding operations.

Narzędzia ANDRE ze spoiwem ceramicznym, dzięki naszemu wieloletniemu doświadczeniu cechuje wysoka jakość. Zespół technologów odpowiada na indywidualne potrzeby użytkowników finalnych wytwarzając narzędzia ścierne o ściśle zaprojektowanych parametrach fizyko-mechanicznych dedykowanych pod konkretne operacje szlifierskie.

Example of vitrified bonded abrasive tool structure

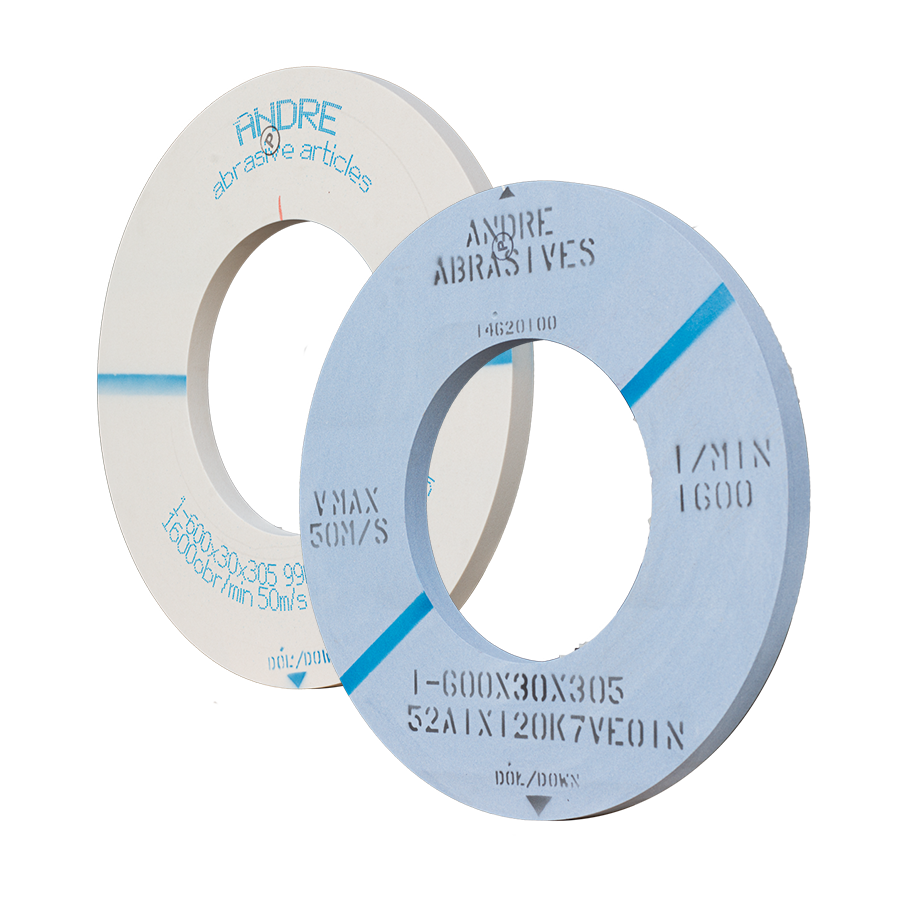

Applications of abrasive tools with vitrified bonds

Various operations

Fine grinding of various materials during surface grinding, cylindrical and centreless grinding, hole grinding, profile and contour grinding and sharpening of cutting tools as well as workshop work

Various industries

Used in many different industries such as automotive, tool and bearing, as well as food and medical

Features of abrasive tools with ceramic bonds

quick material removal

"cool" grinding

high grinding precision

tools high resistance to water and oils

wysoka odporność narzędzi na wodę i oleje

High-quality, proven raw materials

At ANDRE ABRASIVE ARTICLES, modern hard materials are used in the manufacture of ceramic bonded abrasive tools. The most commonly used abrasives are aluminium oxide and silicon carbide in various varieties.

95A - Normal aluminium oxide (brown)

97A - Semifriable aluminium oxide

99A - Friable aluminium oxide (white)

CrA - Chromium aluminium oxide (pink)

M - Monocrystalline aluminium oxide

ZrA - Zirconia aluminium oxide

X - Microcrystalline aluminium oxide

99C - Green silicon carbide

98C- Black silicon carbide

Abrasive tools by ANDRE ABRASIVE ARTICLES are safe.

ANDRE gradually improves its technological process to offer abrasive tools with increasingly better usability and a high safety factor in accordance with the applicable standards. Membership in organizations of leading abrasive tool manufacturers and regular certification fully confirm that.

FEDERATION OF EUROPEAN PRODUCERS OF ABRASIVES