IMPORTANT MATTER: SAFETY

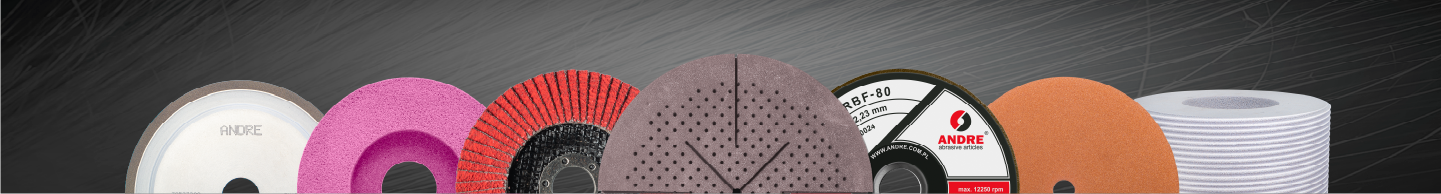

There are many hazards that can occur during the operation of abrasive tools. The key to their safe use is proper operation, proper storage and a high level of safety for the tool itself. At ANDRE, every effort is made to ensure that the products that reach their users are safe.

Safety is a priority

ANDRE products are safe

When it comes to abrasive tool safety, it's all about reducing potential hazards.

Safety is therefore already determined by the design stage of tool construction. Another element is the proper selection of raw materials, followed by ongoing monitoring of each stage of production. Equally important is the verification of all key parameters of the finished product and performance testing.

This is an elementary task of the manufacturer.

Predictable and repeatable products

Professional product verification

For any abrasive tool user, the issue of predictability and repeatability during operation is extremely important.

ANDRE products, before they reach the hands of customers, are verified in accordance with accepted standards, both in terms of quality and safety.

As a result, the safety factor of ANDRE products is at a high level.

Education activities

How to use abrasive tools wisely...

At ANDRE, various activities have been undertaken for many years to educate abrasive tool users about safety. Training courses, tool demonstrations and information materials, focus on the principles of proper operation of abrasive tools and the possible dangers of improper use.

CERTIFIED PRODUCT SAFETY

The sense of responsibility for human life and health, awareness of threats, and increasingly higher industry standards cause ANDRE to constantly care for the safety of its own products and to ensure the highest safety standards in the manufacturing process. ANDRE, gradually improving the technological process, offers abrasive tools that ensure better and better usability values and a high safety factor, in accordance with the directives of various certifications.

oSa - The Organization for the Safety of Abrasives

oSa is an independent organization that brings together and certifies the world's best manufacturers of abrasives. oSa is a symbol of safety and a guarantee of professionalism.

FEPA - Federation of European Producers of Abrasives

ANDRE ABRASIVE ARTICLES was accepted as a member of the European abrasive tool manufacturers' organization FEPA in 2017.

FEPA's main task is to represent the European abrasive industry globally, to promote abrasive tools manufactured in Europe but also to inform its members about changes in the regulatory framework and to support technical information, scientific services and anticipate future challenges in the abrasives sector.

Our membership in FEPA is a sense of belonging to a family of European manufacturers whose main goal is to provide good and safe products.

CONSTANT CONTROL OF PRODUCTS

The manufacturer ensures the application of appropriate procedures in the design and manufacture of its products. The aim of these activities is to ensure the appropriate quality, repeatability and safety of ANDRE grinding tools.

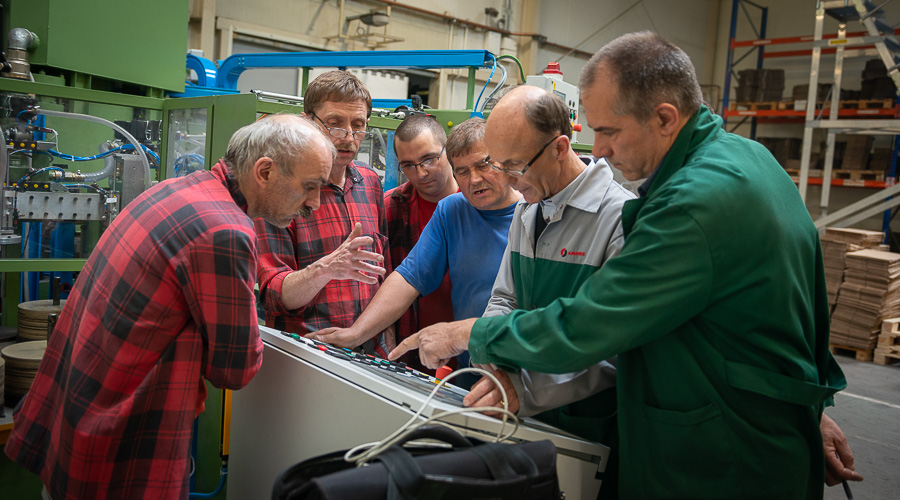

Step-by-step monitoring

Starting from the abrasive grain itself, the bond, through production and to the finished product warehouse

Raw materials, used in the manufacture of abrasive tools, undergo preliminary tests, already at the stage of receipt at the warehouse. Only after approval they can be used to prepare a mixture with the right composition.

In order to maintain optimum product quality at the various stages of production (preparation of mixtures, press forming, firing, etc.), production processes are supervised in detail. Not only the correct settings of machines and equipment is important but also the right conditions of mixture seasoning and optimally selected firing parameters.

Safety without compromise

Actions that are a must

Before the products are put into storage, they undergo a quality inspection aimed at detecting any possible defects.

The inspection of products always involves several stages, although it varies depending on the product range.

First, a visual inspection is carried out and in the case of vitrified bond tools additional sound method is used. It is checked if there are no visible scratches, cracks, chipping and in the case of the sound method, the grinding wheel is tapped to check the type of sound it makes. A properly bonded tool should make clear sound, a damaged one - a muffled sound.

The individual dimensions of the grinding wheels are further verified. With the use of a special measuring device the hardness of the grinding tool is tested. The modulus of elasticity is also checked using electronic non-destructive testing equipment. Grinding wheels are also checked for their allowable unbalance and rotational speed by conducting tests for test speed and burst speed.

Performance testing

Safety and performance testing of abrasive tools

In addition to standard inspection procedures, ANDRE products undergo extensive performance testing.

ANDRE's products are subjected to successive optimization in terms of both quality and performance. Detailed inspection of products, being a part of the manufacturing process, does not end the story. The tools are also subjected to performance tests, where their safety and efficiency are verified during intensive operation.

Performance testing on the one hand is the testing of implemented technological solutions, and on the other hand is the ongoing verification of the quality and safety of ANDRE products.

Storage and shipping

With special care until handed over to the customer

Proper storage and transportation of abrasive tools is one of the important elements affecting product safety.

Grinding wheels, although characterized by high dynamic tensile strength, are sensitive to impacts, falls, bending stresses and for these reasons require particularly careful handling.

At ANDRE's warehouses, products are stored in optimal conditions, including proper temperature, ventilation and finally room humidity.

The product shipped to the customer is properly protected and packed, so that it reaches the "hands" of the user without damage.